Thermoforming is a widely used process for producing plastic parts and packaging due to its cost-effectiveness and versatility. In this article, we will explore why thermoforming is considered a cheap manufacturing process, the factors that influence its cost, and how Sayeah Machinery, a leading manufacturer of automatic plastic thermoforming machines, can help you achieve optimal results at a competitive price.

Understanding Thermoforming and Its Cost Benefits

Thermoforming is a manufacturing process that heats a sheet of plastic to a pliable state and then forms it into a specific shape using a mold. The process is known for its affordability, especially when compared to other plastic molding methods. Let’s dive into the reasons behind its cost-effectiveness:

Material Utilization:

- Thermoforming typically uses thinner sheets of plastic, which reduces material costs compared to injection molding or blow molding.

- Less material waste due to the use of trim and scrap recycling.

Tooling Costs:

- Tooling for thermoforming is generally less expensive than for injection molding because molds do not require the same level of precision.

- Lower upfront investment for molds means quicker return on investment (ROI).

Setup Time:

- Thermoforming machines have shorter setup times, which reduces labor costs associated with machine preparation.

- Quick changeover between different products minimizes downtime.

Production Speed:

- Automated thermoforming machines, like those offered by Sayeah Machinery, can produce parts quickly, leading to higher output rates and lower per-unit costs.

- High-speed production increases capacity and efficiency.

Design Flexibility:

- Thermoforming allows for a wide range of product designs, from simple to complex shapes, without significant tooling modifications.

- Versatility in design means a single machine can handle various product types.

Factors Influencing Thermoforming Costs

While thermoforming is generally considered cost-effective, several factors can affect the overall cost of the process:

Material Type:

- Different types of plastic have varying costs. Polypropylene and polystyrene tend to be less expensive than specialty plastics like PETG or ABS.

Thickness of Material:

- Thicker materials require more heat and pressure, potentially increasing energy consumption and processing time.

Machine Automation:

- Automated machines, such as those manufactured by Sayeah Machinery, can reduce labor costs and improve accuracy, but the initial investment can be higher.

Production Volume:

- Higher volumes lead to lower per-unit costs due to economies of scale.

- Large-scale production can also benefit from bulk material discounts.

Complexity of Product:

- Simple designs are typically cheaper to produce than complex ones, which may require additional trimming or secondary operations.

Post-Processing:

- Additional finishing steps, such as trimming, drilling, or gluing, can add to the final cost.

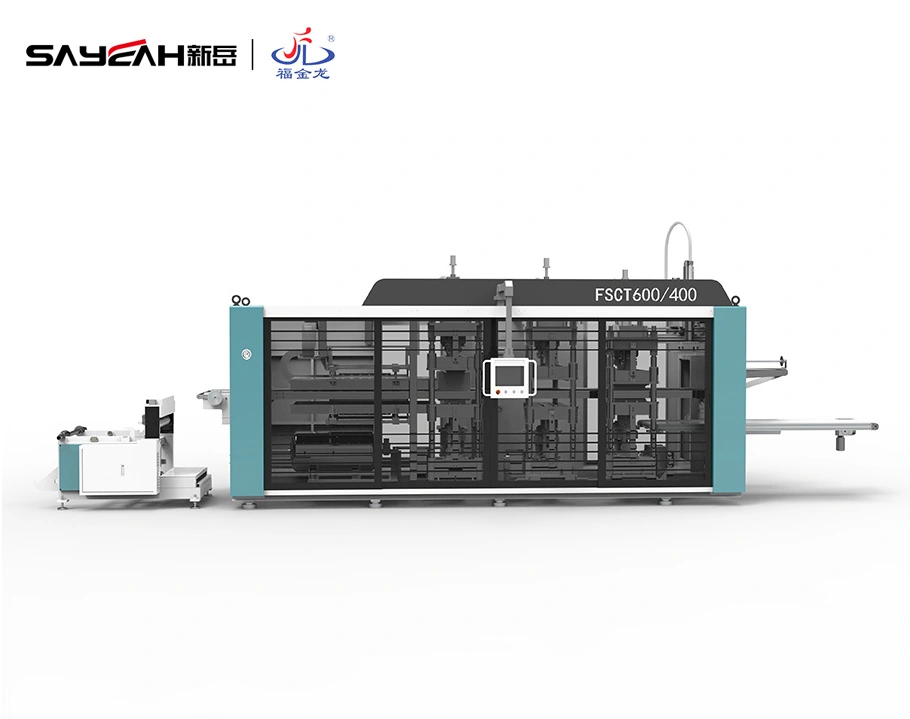

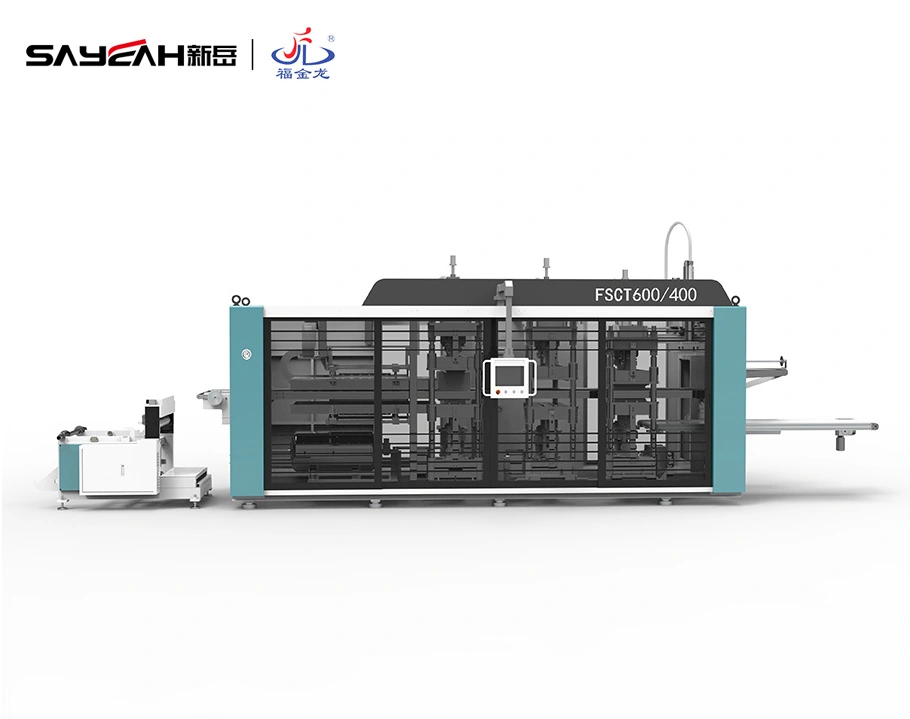

Sayeah Machinery: Affordable Thermoforming Solutions

Sayeah Machinery, a China-based manufacturer, specializes in providing high-quality automatic plastic thermoforming machines designed to meet the specific needs of manufacturers. Here’s how Sayeah Machinery can help you keep costs down:

Customizable Machines:

- Sayeah Machinery offers customizable machines that can be tailored to your specific production requirements.

- Customization ensures that the machine is optimized for your product, reducing waste and improving efficiency.

Affordable Pricing:

- Factory-direct pricing makes Sayeah Machinery’s machines cost-effective, even for smaller manufacturers.

- Bulk purchase discounts available for wholesale orders.

Robust Build Quality:

- Sayeah Machinery’s machines are built to last, ensuring long-term savings on maintenance and repair costs.

- Durable construction reduces the risk of downtime and costly repairs.

Efficient Production:

- Automatic machines minimize labor costs and maximize output.

- Precise temperature control and rapid cycle times enhance productivity.

Technical Support:

- Comprehensive training and support services to help you get the most out of your machine.

- On-site installation and troubleshooting services are available.

Global Distribution:

- Sayeah Machinery has a global distribution network, ensuring prompt delivery and local support wherever you are.

Thermoforming is an economical choice for producing plastic parts and packaging due to its efficient use of materials, low tooling costs, and quick setup times. Sayeah Machinery’s automatic plastic thermoforming machines offer a cost-effective solution for manufacturers looking to streamline their production processes. Whether you’re a small business just starting out or a large-scale manufacturer, Sayeah Machinery can provide the right machine to fit your budget and production needs. Contact Sayeah Machinery today to learn more about how their machines can help you achieve your manufacturing goals.